-

Overview

Overview

Centre Testing International Group Co., Ltd. (CTI) is a market leader in testing, inspection, certification, calibration, audit, training & technical services; building trust between governments, enterprises, and consumers.

-

Sustainability

Sustainability

By building a full value chain ESG governance system covering the strategic decision-making level, management execution level and business operation level, it actively practices penetrating management of ESG risk and opportunities, empowering sustainable development across the industry chain.

-

Our service

Our serviceCentre Testing International Co., Ltd. (CTI) is the pioneer and leader in the TIC Industry which provides one-stop solutions on testing, inspection, certification, calibration, audit, training & technical services.

-

By Industry

Our service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

Environment

Environment

-

Raw Material & Fuel Chemicals

Raw Material & Fuel Chemicals

-

Textiles, Apparel, Footwear & Accessories

Textiles, Apparel, Footwear & Accessories

-

Food & Agricultural Products

Food & Agricultural Products

-

Cosmetics, Personal Care & Household Chemicals

Cosmetics, Personal Care & Household Chemicals

-

Building Materials&Construction Engineering

Building Materials&Construction Engineering

-

Electronic & Electrical Appliances

Electronic & Electrical Appliances

-

Toys, Furniture & Home Decoration

Toys, Furniture & Home Decoration

-

Industrial Equipment & Manufacturing

Industrial Equipment & Manufacturing

-

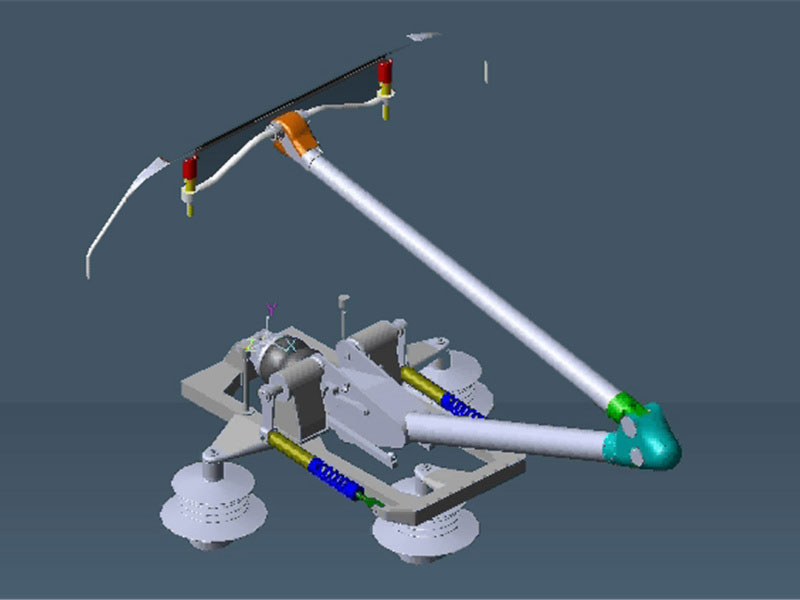

Rail & Aviation

Rail & Aviation

-

Automotive & Spare Parts

Automotive & Spare Parts

-

Pharma and Medical Services

Pharma and Medical Services

-

Maritime Vessel Compliance Testing

Maritime Vessel Compliance Testing

By Industry

By IndustryOur service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

-

Specialty

SpecialtyComprehensively guarantee quality and safety, promote compliance and innovation, demonstrate brand competitiveness, and achieve higher quality, healthier, safer, and greener sustainable development.

-

Management

ManagementWe have established a clear governance structure in accordance with listing requirements and national regulations and policies to deal with internal and external challenges and achieve sustainable development.

-

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

-

Talents Policy

Talents PolicyEnsuring the basic rights and benefits of employees;

Providing professional skills training to promote employees’ growth;

Carrying out various kinds of activities to balance employees’ work and life.

-

RecruitmentWelcome to join CTI family! We are providing a platform for you to show your talents and achieve your career aspiration.

RecruitmentWelcome to join CTI family! We are providing a platform for you to show your talents and achieve your career aspiration.

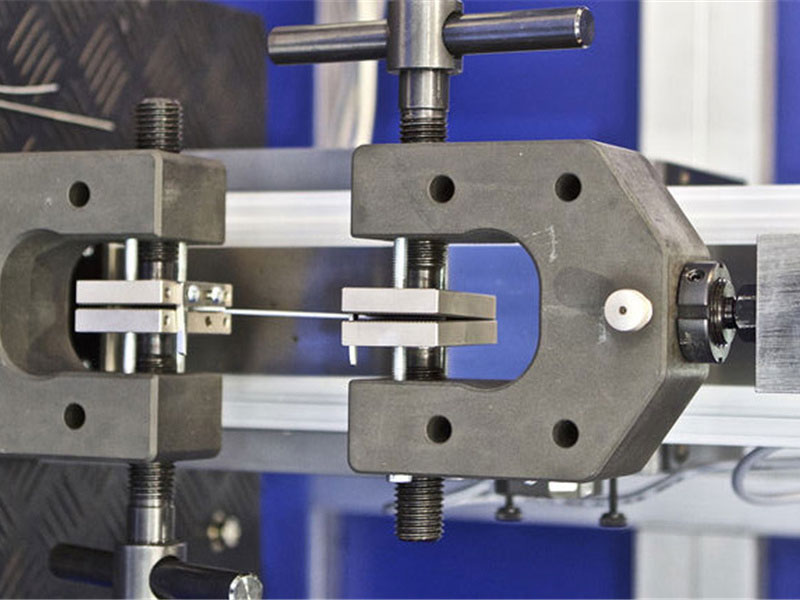

Metallographic analysis is a powerful tool for analyzing and studying various materials, establishing the quantitative relationship between microstructure and properties of materials, and studying the transformation dynamics of materials. CTI can provide high precision and high speed metallographic analysis test items for customers to evaluate materials more scientifically and provide reliable data for rational use of materials.

◉ Service Background

1. Check the quality of raw materials by metallographic analysis;

2. The microstructure parameters of the accepted products were analyzed by metallography;

3. Quality control in the production process, select the appropriate production process;

4. As an important basis for failure analysis.

◉ Service Content

1. Test Items

|

Microstructure analysis |

A method of examining metallic tissue by metallographic microscope. |

|

Etch test for macrostructure and defect of steels |

Etch test for macrostructure and defect of steels |

|

Determination of the average grain size |

Intercept method: Measure the grain size by counting the number of points at which the measured segment of a given length intersects the grain boundary. |

|

Evaluation of the nonmetallic inclusion |

The view observed by the metallographic was compared with the inclusions map, and the inclusions were rated separately. |

|

Metallographical for the gray cast iron |

Graphite distribution shape, graphite length, carbide distribution shape, carbide quantity, phosphorus eutectic type, phosphorus eutectic distribution shape, phosphorus eutectic quantity |

|

Metallographical for the ductile iron |

Spheroidization grading, graphite size grading, ferrite and pearlite number grading, phosphorus eutectic number, cementite number |

|

Case hardening depth |

Metallographic method, hardness method |

|

Determination of depth of decarburization |

Metallographic method, hardness method |

|

Phase content of stainless steel |

Comparison of maps |

|

Eutectic carbide |

The worst field of view was compared with the map |

2. Applicable product scope

Applicable to metal materials and the products, including::

Steel materials: carbon steel, stainless steel, heat resistant steel, alloy steel, cast iron, etc.

Nonferrous metals: aluminum alloy, copper alloy, titanium alloy, etc.

Other metal products: profiles, plates, pipes, fasteners, castings, parts, mechanical equipment and components, etc.

3. General sample requirements

|

Microstructure analysis |

grinding area<400mm2,H:15mm~20mm |

|

Etch test for macrostructure and defect of steels |

1. 250mm*H*20mm 2. customer request |

|

Determination of the average grain size |

Metal Type |

|

Evaluation of the nonmetallic inclusion |

1. Longitudinal section≥20mm*10mm 2. Small thickness, diameter or wall thickness,area<200mm2,contact us. |

|

Metallographical for the gray cast iron |

grinding area<400mm2,H:15mm~20mm |

|

Metallographical for the ductile iron |

grinding area<400mm2,H:15mm~20mm |

|

Case hardening depth |

cross section |

|

Determination of depth of decarburization |

1. small parts, the whole section,thickness<5mm 2. larger parts,Cut off part of the cross section,includes the entire decarbonized layer,thickness>5mm |

|

Phase content of stainless steel |

Axial length:10mm~15mm |

|

Eutectic carbide |

Axial length:10mm~12mm |

◉ Our Strengths

1. Experienced technicians to provide detailed technical advice and result analysis;

2. Advanced high-end and automatic testing equipment, providing a variety of testing solutions;

3. Complete test and result reporting process to ensure accurate and reliable test results.

粤公网安备 44030602000441号

粤公网安备 44030602000441号