-

Overview

Overview

Centre Testing International Group Co., Ltd. (CTI) is a market leader in testing, inspection, certification, calibration, audit, training & technical services; building trust between governments, enterprises, and consumers.

-

Sustainability

Sustainability

By building a full value chain ESG governance system covering the strategic decision-making level, management execution level and business operation level, it actively practices penetrating management of ESG risk and opportunities, empowering sustainable development across the industry chain.

-

Our service

Our serviceCentre Testing International Co., Ltd. (CTI) is the pioneer and leader in the TIC Industry which provides one-stop solutions on testing, inspection, certification, calibration, audit, training & technical services.

-

By Industry

Our service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

Environment

Environment

-

Raw Material & Fuel Chemicals

Raw Material & Fuel Chemicals

-

Textiles, Apparel, Footwear & Accessories

Textiles, Apparel, Footwear & Accessories

-

Food & Agricultural Products

Food & Agricultural Products

-

Cosmetics, Personal Care & Household Chemicals

Cosmetics, Personal Care & Household Chemicals

-

Building Materials&Construction Engineering

Building Materials&Construction Engineering

-

Electronic & Electrical Appliances

Electronic & Electrical Appliances

-

Toys, Furniture & Home Decoration

Toys, Furniture & Home Decoration

-

Industrial Equipment & Manufacturing

Industrial Equipment & Manufacturing

-

Rail & Aviation

Rail & Aviation

-

Automotive & Spare Parts

Automotive & Spare Parts

-

Pharma and Medical Services

Pharma and Medical Services

-

Maritime Vessel Compliance Testing

Maritime Vessel Compliance Testing

By Industry

By IndustryOur service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

-

Specialty

SpecialtyComprehensively guarantee quality and safety, promote compliance and innovation, demonstrate brand competitiveness, and achieve higher quality, healthier, safer, and greener sustainable development.

-

Management

ManagementWe have established a clear governance structure in accordance with listing requirements and national regulations and policies to deal with internal and external challenges and achieve sustainable development.

-

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

-

Talents Policy

Talents PolicyEnsuring the basic rights and benefits of employees;

Providing professional skills training to promote employees’ growth;

Carrying out various kinds of activities to balance employees’ work and life.

-

RecruitmentWelcome to join CTI family! We are providing a platform for you to show your talents and achieve your career aspiration.

RecruitmentWelcome to join CTI family! We are providing a platform for you to show your talents and achieve your career aspiration.

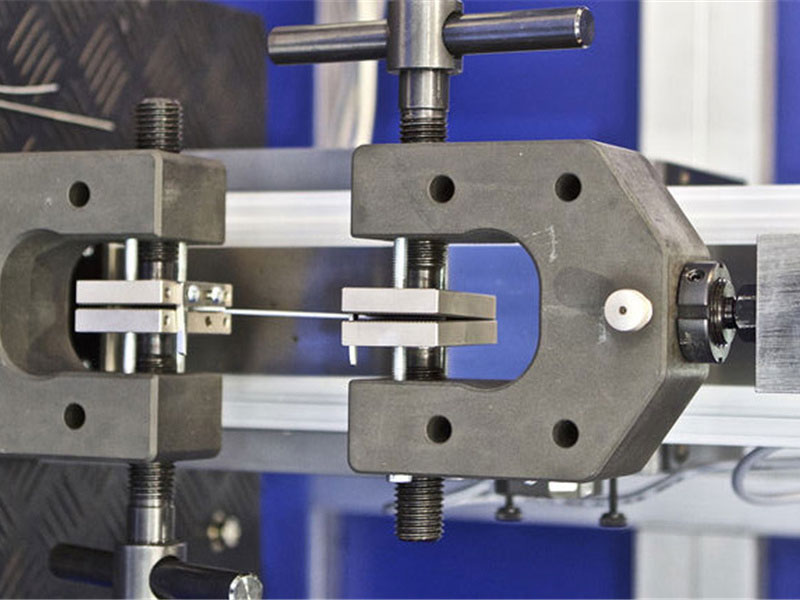

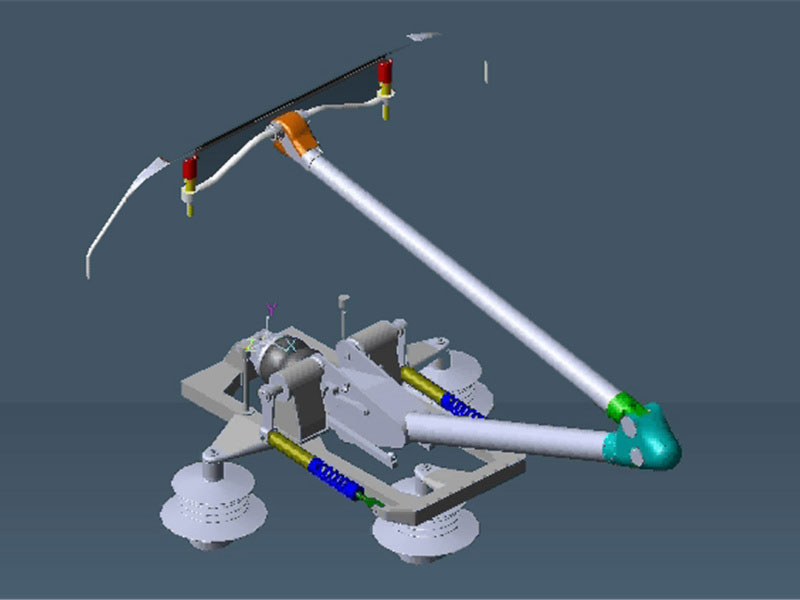

Product quality is the foundation of an enterprise. CTI provides customized failure analysis solutions,To help enterprises reduce and prevent the recurrence of failure of similar mechanical parts, ensure product quality, improve product competitiveness, provide information for enterprise technology development, technical transformation, increase the technical content of enterprise products, so as to obtain greater economic benefits.

◉ Service background

1、Determine failure mode;

2、Define failure defect;

3、Identify failure mechanism;

4、Determine failure cause;

5、Put forward countermeasure.

◉ Service Content

1、Main failure type

|

Fracture failure |

Cleavage fracture failure,dimple fracture failure,quasi cleavage fracture failure,fatigue fracture failure,creep fracture failure,stress corrosion fracture failure,intergranular fracture failure,liquid or solid metal brittle fracture failure,hydrogen embrittlement fracture failure,slip separation failure,etc. |

|

Deformation failure |

Elastic deformation failure and plastic deformation failure. |

|

Wear failure |

Adhesion wear failure、abrasive wear failure、corrosion wear failure、deformation wear failure、surface fatigue wear failure、impact wear failure、micro vibration wear failure,etc. |

|

Corrosion failure |

Direct chemical、electrochemical corrosion failure、point corrosion failure、local corrosion failure、intergranular corrosion failure、selective corrosion failure、crevice corrosion failure、wear corrosion failure、hydrogen damage failure、stress corrosion failure,etc. |

2、Product scope

Metal materials and parts、fastening bolts、shaft parts、gears、spiral springs、plate springs、connecting rods,etc.

3、Failure analysis test method

|

Chemical analysis |

OES、ICP-OES、EDS、XRF、carbon sulfur analyzer 、Oxygen nitrogen hydrogen analyzer、XRD |

|

Mechanical properties test |

Tensile test、Impact test 、Bend test 、flattening/flaring/flange test、shear test、compression test |

|

Hardness test |

Brinell Hardness、Rockwell Hardness、Vickers Hardness、Micro Vickers Hardness、Knoop hardness |

|

Metallographic analysis |

micro-structure 、grain size、the nonmetallic inclusion、coating thickness、macro test |

|

Fracture analysis |

Stereo-microscope analysis、SEM analysis |

|

异物分析 |

SEM-EDS |

|

Corrosion testing |

NSS、AASS、CASS、cyclic salt spray test、intergranular corrosion、Dezincification resistance of copper alloys |

|

Non-destructive test |

UT、MT、PT、ET、RT |

◉ Service Process

◉ Our Strengths

- Professional failure analysis team

- Complete failure analysis equipment

- Complete failure analysis process

- Advanced failure analysis platform

粤公网安备 44030602000441号

粤公网安备 44030602000441号