-

Overview

Overview

Centre Testing International Group Co., Ltd. (CTI) is a market leader in testing, inspection, certification, calibration, audit, training & technical services; building trust between governments, enterprises, and consumers.

-

Sustainability

Sustainability

By building a full value chain ESG governance system covering the strategic decision-making level, management execution level and business operation level, it actively practices penetrating management of ESG risk and opportunities, empowering sustainable development across the industry chain.

-

Our service

Our serviceCentre Testing International Co., Ltd. (CTI) is the pioneer and leader in the TIC Industry which provides one-stop solutions on testing, inspection, certification, calibration, audit, training & technical services.

-

By Industry

Our service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

Environment

Environment

-

Raw Material & Fuel Chemicals

Raw Material & Fuel Chemicals

-

Textiles, Apparel, Footwear & Accessories

Textiles, Apparel, Footwear & Accessories

-

Food & Agricultural Products

Food & Agricultural Products

-

Cosmetics, Personal Care & Household Chemicals

Cosmetics, Personal Care & Household Chemicals

-

Building Materials&Construction Engineering

Building Materials&Construction Engineering

-

Electronic & Electrical Appliances

Electronic & Electrical Appliances

-

Toys, Furniture & Home Decoration

Toys, Furniture & Home Decoration

-

Industrial Equipment & Manufacturing

Industrial Equipment & Manufacturing

-

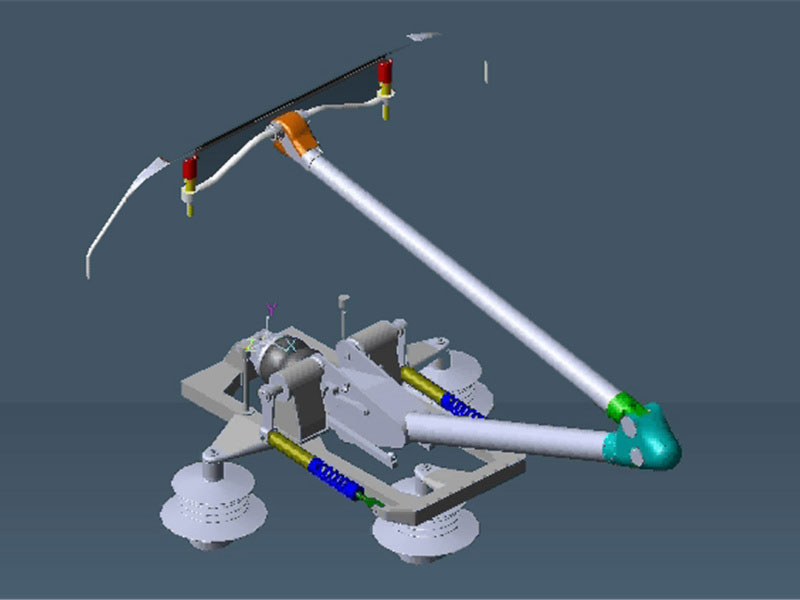

Rail & Aviation

Rail & Aviation

-

Automotive & Spare Parts

Automotive & Spare Parts

-

Pharma and Medical Services

Pharma and Medical Services

-

Maritime Vessel Compliance Testing

Maritime Vessel Compliance Testing

By Industry

By IndustryOur service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

-

Specialty

SpecialtyComprehensively guarantee quality and safety, promote compliance and innovation, demonstrate brand competitiveness, and achieve higher quality, healthier, safer, and greener sustainable development.

-

Management

ManagementWe have established a clear governance structure in accordance with listing requirements and national regulations and policies to deal with internal and external challenges and achieve sustainable development.

-

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

-

Talents Policy

Talents PolicyEnsuring the basic rights and benefits of employees;

Providing professional skills training to promote employees’ growth;

Carrying out various kinds of activities to balance employees’ work and life.

-

RecruitmentWelcome to join CTI family! We are providing a platform for you to show your talents and achieve your career aspiration.

RecruitmentWelcome to join CTI family! We are providing a platform for you to show your talents and achieve your career aspiration.

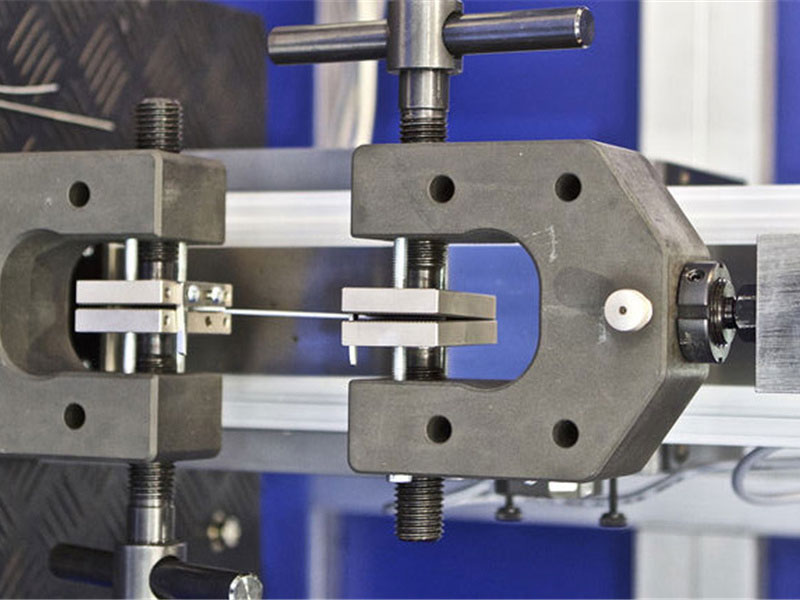

We can provide qualitative/quantitative analysis of sample composition according to customer requirements. Metal material analysis through a variety of equipment and methods to analyze the sample composition, proportion, combined with product application and technical engineer's industry experience, to provide customers with more ideas for material performance improvement, product research and development.

◉ Service background

- Not sure the material designation;

- Want to know the cause of the properties of metal materials;

- To develop better production processes;

- Failure analysis.

◉ Service Content

1、Test methods and standards

|

OES |

GB/T 11170,ASTM E1086 (Stainless steel) GB/T 4336,ASTM E415 (Carbon steel and low alloy steel) GB/T 24234(White cast iron),JIS G1253 (Steel) ASTM E1999(Cast iron),YS/T 482(Copper alloy) GB/T 7999,ASTM E1251,JIS H1305 (Aluminium and aluminium alloy) DIN EN 12019(Zinc alloy), JIS H1322,GB/T 13748.21(Magnesium alloy) |

|

ICP-OES |

GB/T 20125 (Carbon steel and low alloy steel),SN/T 2718 (Stainless steel) GB/T 20975.25(Aluminium and aluminium alloy) GB/T 5121.27,YS/T 586(Copper alloy), GB/T 12689.12(Zinc alloy) GB/T 13748.20(Magnesium alloy), GB/T 10574.13(solder) HB 7716.13(Titanium alloy), GB/T 8647.9,GB/T 14265(Nickel alloy) |

|

Carbon-sulfur analyzer |

GB/T 14265, GB/T 20123, GB/T 5121.4, ASTM E1019, JIS G1211, ISO 15350 |

|

Nitrogen oxygen hydrogen analyzer |

GB/T 5121.8 (Pure copper), GB/T 11261, GB/T 14265, ASTM E1019,JIS Z2613,ASTM E1409 (Titanium alloy), GB/T 20124, JIS G1228, GB/T 223.82, JIS Z2614 |

|

XRF |

GB/T 16597-2019 |

|

Wet chemical method(gravimetric/titration/colorimetric/spectrophotometric method,etc) |

GB/T 5121.1-2008 Electrolytic copper YS/T 910-2013(titration)Electrolytic copper GB/T 10574.1-2003 Lead solder titrate |

|

EDS |

GB/T 17359-2012, ASTM E1508-98(2012) |

2、Applicable product scope

Metal materials and products (including black metal: carbon steel, stainless steel, heat-resistant steel, alloy steel, cast iron, nonferrous metals, aluminium and aluminium alloy, copper and copper alloy, nickel base alloy, solder, rare metals, rare earth metals, high purity metal, pure iron, pure aluminum, magnesium, zinc, pure tin, pure copper, special metal materials: function alloy, metal matrix composites, etc.

3、General sample requirements

|

OES |

L×W×H: 15mm×15mm×2mm, at least rod: Minimum diameter φ15mm tube: Minimum thickness 2mm note: 1、Rods and tubes may be suitably flattened to form a plane on one side. 2、Ensure the material designation,if necessary. |

|

ICP-OES |

Sample needs:>20g (Precious metals,>2g), if not enough,pls contact with us. note: Ensure the material designation,if necessary. |

|

XRF |

Minimum diameter φ15mm,Powder samples>0.1g |

|

EDS |

A solid sample of nonaqueous or nonaqueous and volatile matter; Non-magnetic sample powder sample subject to confirmation by the engineer; size:Max. 4cm*4cm*3.5cm. |

|

C/S |

10g |

|

O/N/H |

massive sample>φ5mm, other sample, please contact us. |

◉ Our Strengths

- More experience in material analysis.

- Professional technical personnel.

- Advanced analysis equipment and process.

粤公网安备 44030602000441号

粤公网安备 44030602000441号