-

Overview

Overview

Centre Testing International Group Co., Ltd. (CTI) is a market leader in testing, inspection, certification, calibration, audit, training & technical services; building trust between governments, enterprises, and consumers.

-

Sustainability

Sustainability

By building a full value chain ESG governance system covering the strategic decision-making level, management execution level and business operation level, it actively practices penetrating management of ESG risk and opportunities, empowering sustainable development across the industry chain.

-

Our service

Our serviceCentre Testing International Co., Ltd. (CTI) is the pioneer and leader in the TIC Industry which provides one-stop solutions on testing, inspection, certification, calibration, audit, training & technical services.

-

By Industry

Our service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

Environment

Environment

-

Raw Material & Fuel Chemicals

Raw Material & Fuel Chemicals

-

Textiles, Apparel, Footwear & Accessories

Textiles, Apparel, Footwear & Accessories

-

Food & Agricultural Products

Food & Agricultural Products

-

Cosmetics, Personal Care & Household Chemicals

Cosmetics, Personal Care & Household Chemicals

-

Building Materials&Construction Engineering

Building Materials&Construction Engineering

-

Electronic & Electrical Appliances

Electronic & Electrical Appliances

-

Toys, Furniture & Home Decoration

Toys, Furniture & Home Decoration

-

Industrial Equipment & Manufacturing

Industrial Equipment & Manufacturing

-

Rail & Aviation

Rail & Aviation

-

Automotive & Spare Parts

Automotive & Spare Parts

-

Pharma and Medical Services

Pharma and Medical Services

-

Maritime Vessel Compliance Testing

Maritime Vessel Compliance Testing

By Industry

By IndustryOur service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

-

Specialty

SpecialtyComprehensively guarantee quality and safety, promote compliance and innovation, demonstrate brand competitiveness, and achieve higher quality, healthier, safer, and greener sustainable development.

-

Management

ManagementWe have established a clear governance structure in accordance with listing requirements and national regulations and policies to deal with internal and external challenges and achieve sustainable development.

-

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

-

Talents Policy

Talents PolicyEnsuring the basic rights and benefits of employees;

Providing professional skills training to promote employees’ growth;

Carrying out various kinds of activities to balance employees’ work and life.

-

RecruitmentWelcome to join CTI family! We are providing a platform for you to show your talents and achieve your career aspiration.

RecruitmentWelcome to join CTI family! We are providing a platform for you to show your talents and achieve your career aspiration.

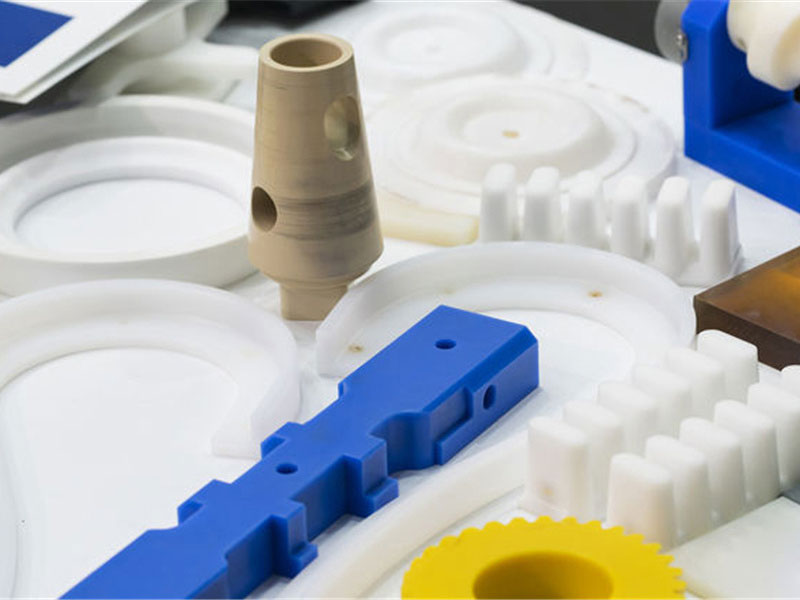

Failure analysis has strong practical significance in improving product quality, technology development, improvement, product repair and arbitration of failure accidents. CTI is a third-party laboratory focusing on failure analysis technology services. it has established a good reputation in the industry due to the service in the field of failure analysis with many years.Its independent third-party status, a large number of accumulated cases and databases enable us to provide customers with fair, independent and accurate failure analysis reports.

◉ Background

The NG part provided by the customer is a flange plate made of polyoxymethylene, which is white before processing, but after normal processing, a certain percentage of the product has a partial yellowing phenomenon.

Diagnostic analysis: uneven local heating leads to overheating of the failure part and yellowing.

◉ Suggestions for Improvement

1. Improving the injection molding process to ensure the temperature uniformity of each part;

2. Under the premise of ensuring quality, appropriately lowering the temperature and reducing the amount of stabilizer added.

◉ Service Content

Ⅰ. CTI uses comprehensive diversified analysis and testing methods to analyze the main failure causes for you:

1. Design a failure analysis plan based on the characteristics and failure characteristics of the product.

2. Comprehensive analysis, including but not limited to morphology analysis, physical property analysis, component analysis and reproducibility test, etc.

3. Comprehensive comparison and analysis of failed products and qualified products, infer the most likely cause of failure or eliminate factors that affect failure.

4. Provide suggestions for improvement to reduce or avoid the recurrence of failures.

Ⅱ. Common failure modes and causes

Discoloration failure (photochromic, electrochromic, thermochromic, aging discoloration); Fracture failure (brittle fracture, ductile fracture);

Delamination failure (moisture, corrosion, popcorn effect, thermal stress, passivation layer defects, plastic forming defects, die attach defects);

Corrosion failure (chemical cracking, swelling and dissolution, stress corrosion cracking, penetration failure);

Crack failure (orientation residual internal stress, cooling residual internal stress, environmental stress);

Wear failure (sliding wear, abrasive wear, erosion wear);

Frost spray failure (accelerator and antioxidant spray, sulfur spray, filler spray, softener, plasticizer, lubricant spray);

Foaming failure (vapor pressure, osmotic pressure, chemical reaction, residual gas in the substrate, residual solvent in the paint, poor adhesion of the primer).

Ⅲ. Failure Analysis Object

Plastics, rubber, adhesives, natural latex, composite materials, coatings, oils, etc.

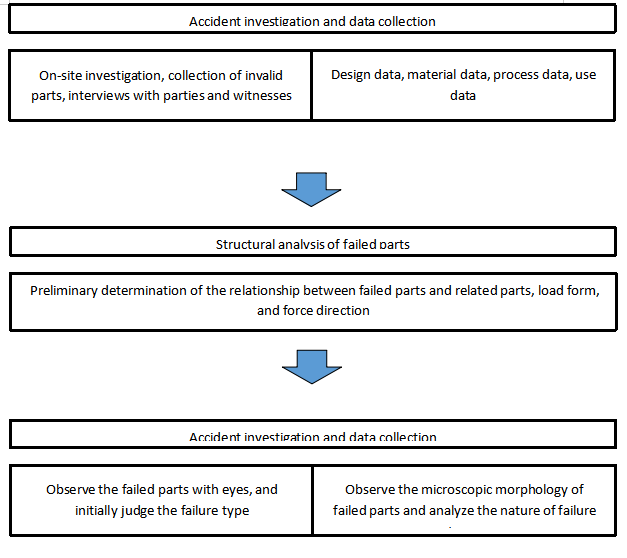

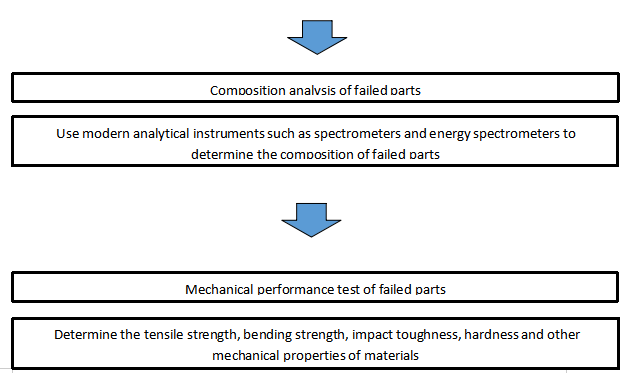

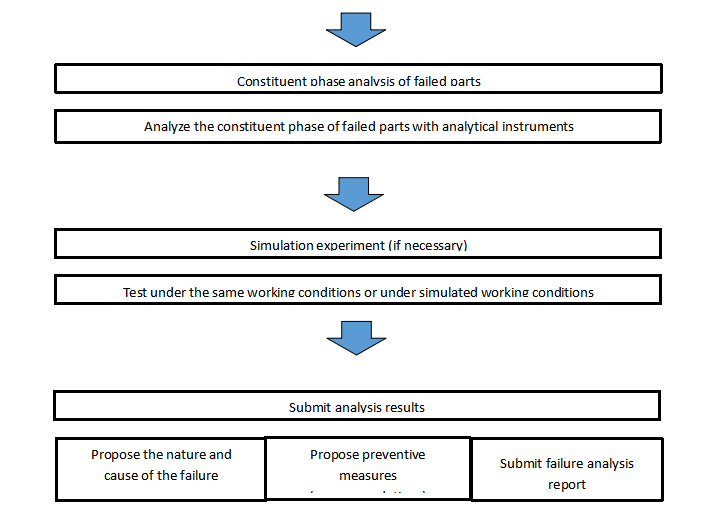

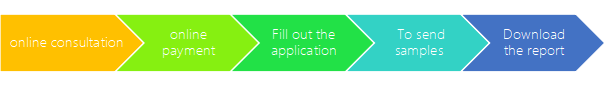

General flow of failure analysis workflow

◉ Advantages

1. We focus on your needs and solve your problems purposefully and systematically.

2. Led by experienced professors, the CTI team can quickly judge and analyze various failure types.

3. We can provide enterprises with multi-directional services and provide clear directions and suggestions for material improvement.

◉ Service Process

粤公网安备 44030602000441号

粤公网安备 44030602000441号